Product Overview

Fatigue Damage Spectrum (FDS) allows users to compare the potential damage caused by different Random and Swept Sine profiles. In a similar fashion to Multi-Sine Control, FDS provides a way to reduce testing times by calculating the quickest path to destruction or damage. Testing times are accelerated by focusing random or swept Sine energy, depending on the FDS calculation, to where it will induce the most fatigue.

Learn MoreKey Features

Continuous Data Recording

During vibration control, all measurement input and drive signals can continuously record to a Spider-NAS or the internal storage residing in each front-end. Users can view and analyze data files with Crystal Instruments Post Analyzer. The variable sampling rate can be enabled to simultaneously record slow-change signals together with high speed vibration data.

Multi-Resolution for Random Vibration Control

EDM provides the powerful multi-resolution feature that applies the selected resolution in the high-frequency range and 8 times of the resolution in the low-frequency range. The cut-off frequency, which divides the low and high-frequency range, is calculated by the software.

Available Options

For further information on options available for this Product, please contact our specialist sales team on:

+44 (0) 1462 481859 or

Resources

Request Quote

Please select the form below relevant to your enquiry:

Hardware

- Spider-81 Premium Vibration Controller

- Spider-81B Basic Vibration Controller

- Spider-80X High Channel Vibration Controller – Scale up to 512 Channels

- Spider-80Xi High Channel Vibration Controller – Compact, handheld high channel system

- Spider-80M – MIMO Vibration Control System

Software

- Random Vibration Control

- Mixed Mode Vibration Control

- Kurtosis Control for Vibration Testing

- Fatigue Damage Spectrum in Random Vibration Testing

Monitoring Through EDM Cloud

All tests in EDM-VCS support status checks through EDM Cloud. With EDM Cloud support, users can set up any VCS test to upload live data or run logs for completed tests to a cloud storage space provided by Crystal Instruments, where data is securely stored in the user’s account.

The EDM Cloud website is located at https://cloud.go-ci.com. Users can access EDM Cloud from anywhere in the world to check the status of past and current tests. A secure login flow ensures the status can only be checked by authorized personnel with proper credentials. Multiple logins for accessing the same Cloud account is available.

Additional Information

Generate the random profile from time stream data recorded in real-world and see its Fatigue Damage Spectrum (FDS) to know the potential damage. Users can adjust the profile to reduce testing time.

- Max Number of Profile Points: 400

- Display: APS and FDS

- Options: low and high frequency at 1/24 octave max, target life and test duration.

The damage caused by vibration can be caused in one of the following conditions:

- Damage caused by an extreme instantaneous stress on an object

- Damage caused by fatigue when high amount of a certain stress is applied to the object

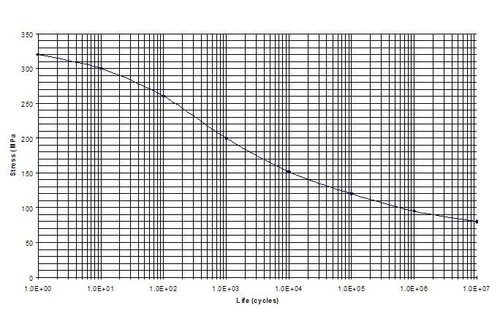

FDS represents a spectrum with regard to the fatigue damage on an object. FDS function makes use of the S-N curve to construct the spectrum. The S-N curve represents the stress applied to a material (S) versus the number of cycles of applied stress. The S-N curve of aluminum is shown below:

Figure 1. S-N Curve of Aluminum

The FDS function helps reduce testing time by calculating the quickest path to destruction or damage. Testing time is accelerated by concentrating the random or swept sine energy, depending on the FDS calculation, to where it will induce the most fatigue damage.

In short, FDS helps the user understand which profile will cause more damage on the object and use this information along with other parameters such as kurtosis to reduce testing time.

VCS Brochure

VCS Brochure