Markets

Industrial / Electronics / Automotive / Renewable Energy / Aerospace / Defence / Ground TransportationModels

- A12/SA1HAM /

- A12/EM1HAM /

- A22/SA2HAM /

- A22/EM2HAM /

- A30/SA3HAM /

- A30/EM3HAM /

- A45/SA5HAM /

- A45/EM5HAM /

- A65/SA6HAM /

- A65/EM7HAM /

- A74/EM8HAM /

- A74/EM10HAM

Specifications

Click HereProduct Overview

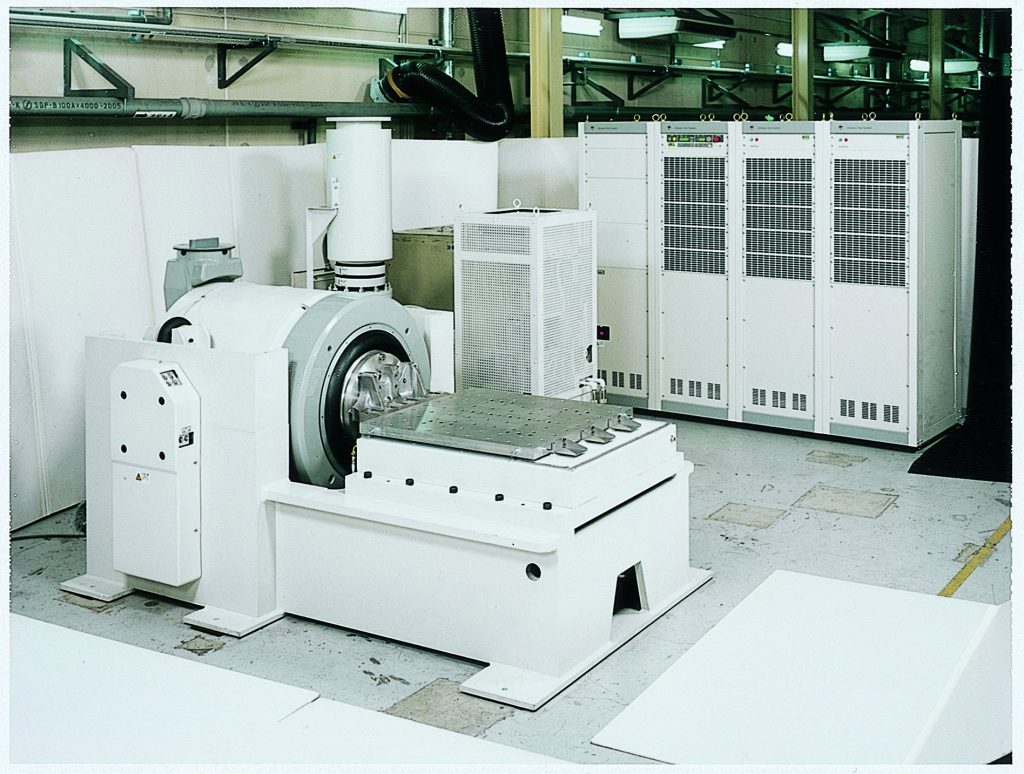

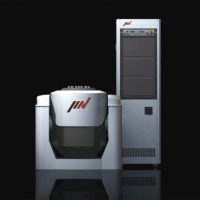

New Standard in Vibration Testing with a solid test performance. The new A-series Vibration Test System from IMV Corporation.

A-series is delivered with high performance as standard responding to the increasing demand of higher test specifications, a comfortable test environment for all people involved in testing and offers an exceptional test performance.

Learn MoreControl System

Launcher

Rapid creation of a test from a set of pre-defined templates conforming to most international test standards.

System Monitor

Remote monitoring of the test status over the internet.

The status of the test, and the amplifier or shaker operation can be viewed on a remote PC using a standard internet browser. Problems or errors are easily identified.

Home Screen

Home Screen (Error)

Eco Screen

Camera Screen

Chamber Screen

Key Features

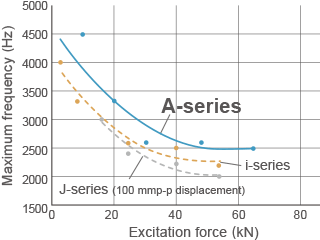

- Improvement in excitation force

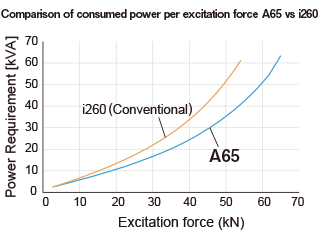

When compared with the conventional i & J series, the A series increases the relative excitation force.- Increased force per system power requirement

- Increased force per system mass

- Increased force per system size

- Standard 76.2 mmp-p displacement

*Only for A30, A45, A65, A74A-series has a displacement of 76.2 mmp-p (3 inch stroke) which gives good balance between specification of velocity, acceleration and displacement. This single system can be used in a very wide variety of tests.

- Increase in frequency range

In addition to the increased displacement of 76.2 mmp-p, the maximum frequency range is also increased when compared to the i, and J-series.

- Cross-axis acceleration reduction

A series dramatically reduces cross-axis (crosstalk) acceleration (horizontal vibration). Highly accurate testing is achieved.

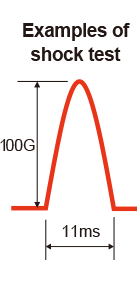

- High velocity shock testing

*Only for A30, A45, A65, A74Where a test requires a high shock velocity, traditional shaker systems use a matching transformer to achieve the necessary higher armature voltage.

Since IMV’s ECO-system has complete control over the field level, the field value can be adjusted to increase the maximum shock velocity capability of the system. By entering the specified shock profile into IMV’s K2 controller. The field level in the shaker is automatically adjusted to ensure that the required velocity is achieved. A-series (EM amplifier model) provides a maximum of 4.6 m/s shock velocity testing.

i-series (conventional)

J-series (conventional)

A-series

- Lower power consumption

In comparison with the same class of conventional systems (i,J-series), the A-series achieves lower power consumption. With an automatic energy-saving function increased energy saving is achieved across all force ranges.

- International safety standards

A-series complies with international safety standards.

Available Options

ECO-Shaker

ECO-shaker is an electrodynamic vibration test system in which the output of the power amplifier, power input to the vibration generator and cooling blower speed are automatically optimised, according to the payload and test requirements.

Complicated manual settings are no longer needed. Changes in the operating environment or in test level are accommodated without operator intervention.

Features

- Only vibration test levels need to be set

- Automatic response to changes in sample under test or test level

- Continuous monitoring of temperatures used to control blower speed

High performance slip table

Hydrostatic-Bearing Slip Tables from IMV Corporation are of the latest design and use hydro-static bearing blocks which are attached to the underside of the slip plate to enhance the performance of the test system.

Features

- High moment resistance

- Low cross-axis acceleration

- Low distortion

- No requirement for a separate hydraulic unit

- Good work efficacy

- Smaller system installation space

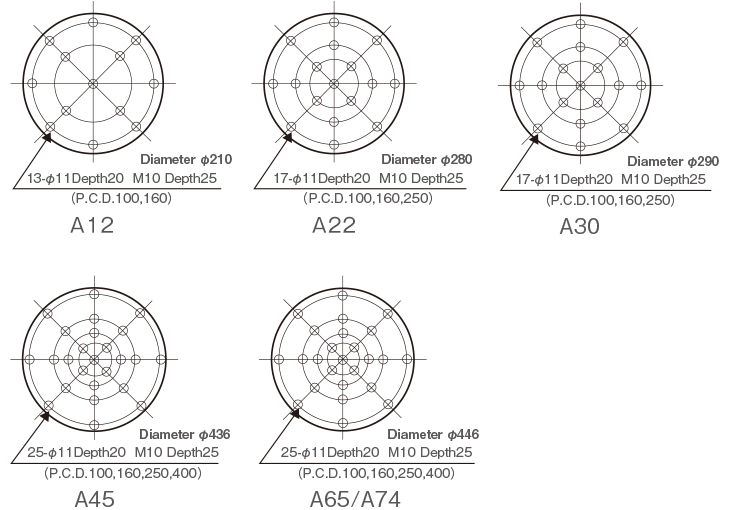

Variable Armature Insert Pattern

The option to freely select the table insert pattern on the shaker armature.

- Selecting this option, the armature mass will increase.

- Due to combining with other options; the horizontal slip table, insert pattern may have restrictions

Head Expanders

The purpose of a Head Expander is to allow testing of multiple items simultaneously, or expanding the test area of a shaker for larger test samples.

Head Expanders can increase efficiency, or simply expand your test capabilities on an existing Vibration Test System.

Features

- Increase Efficiency – Test Multiple Items Simultaneously

- Expand Test Capabilities

Resources

Request Quote

Please select the form below relevant to your enquiry:

A-Series A12

A-Series A12