Models

- J230/SA3AM /

- J230S/SA7AM /

- J240/SA4AM /

- J240S/SA9AM /

- J250/SA5AM /

- J250/SA6AM /

- J260/SA7AM /

- J260S/SA30AM /

- EM2305A /

- EM2405A /

- EM2505A /

- EM2506A /

- EM2605A

Specifications

Click HereProduct Overview

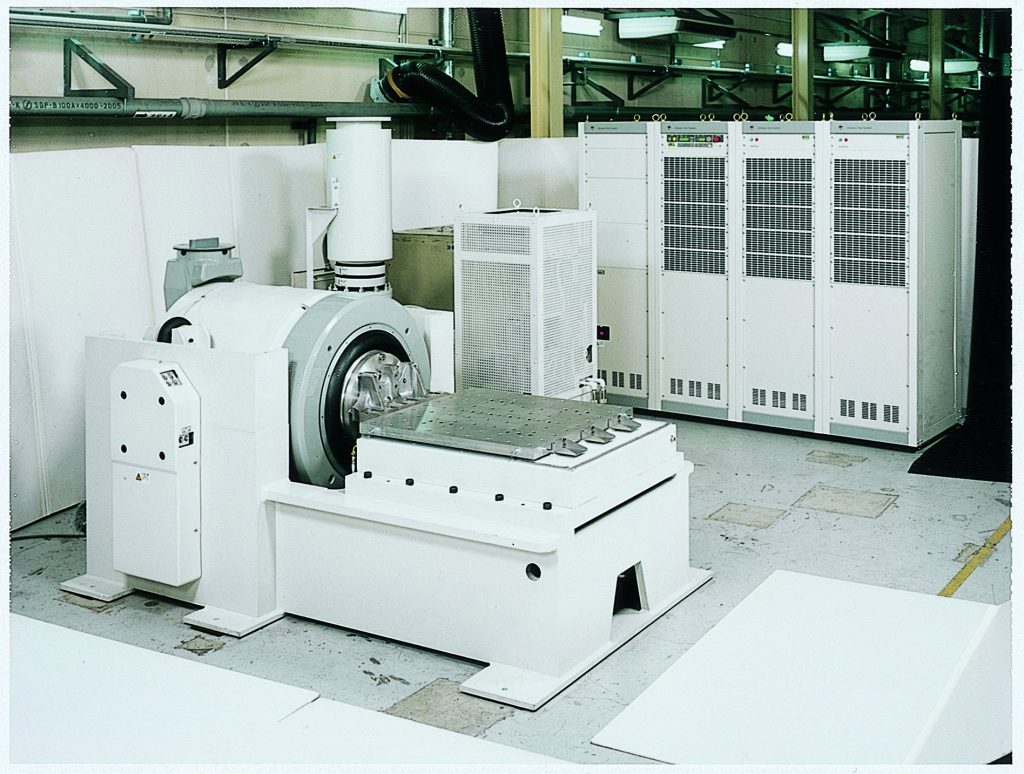

Ideal for high velocity, high-displacement testing, the J-Series Large Displacement Type Vibration Test System from IMV is a high-functionality system that offers both usability and durability coupled with functions and technology that is exclusive to the IMV range of air-cooled vibration test systems.

Designed to cope with long duration shock tests the J-Series Shaker featured an expanded maximum test range, including a maximum velocity of SINE force: 2.4m/s, a maximum velocity of Shock force of 4.6m.s and a maximum displacement of 100mm.

IMV’s Parallel Support Guide System (PSG) supports the upper armature. The PSG significantly improves both durability, reliability of the system resulting in a higher quality of vibration.

The PSG’s compact design provides adequate stiffness and rigidity when compared to a roller support system. This is achieved by an alternative alignment of gears that have a unique curve called an involute curve.

IMV’s J-Series high velocity and high-displacement test system is a world-class solution with nine models in the series.

Learn MoreControl System

Launcher

Rapid creation of a test from a set of pre-defined templates conforming to most international test standards.

System Monitor

Remote monitoring of the test status over the internet.

The status of the test, and the amplifier or shaker operation can be viewed on a remote PC using a standard internet browser. Problems or errors are easily identified.

Home Screen

Home Screen (Error)

Eco Screen

Camera Screen

Chamber Screen

Key Features

- Expanded maximum test range

- Maximum velocity of Sine force: 2.4m/s

- Maximum velocity of Shock force: 4.6m/s

- Maximum displacement: 100mmp-p

- Patented upper (armature) support system PS Guide

Parallel Slope Guide is standard - Low noise

Optimised design of the air intake based on fluid dynamics has reduced the air-intake noise. - All models can be directly coupled to a climatic test chamber

Available Options

ECO-Shaker

ECO-shaker is an electrodynamic vibration test system in which the output of the power amplifier, power input to the vibration generator and cooling blower speed are automatically optimised, according to the payload and test requirements.

Complicated manual settings are no longer needed. Changes in the operating environment or in test level are accommodated without operator intervention.

Features

- Only vibration test levels need to be set

- Automatic response to changes in sample under test or test level

- Continuous monitoring of temperatures used to control blower speed

High performance slip table

Hydrostatic-Bearing Slip Tables from IMV Corporation are of the latest design and use hydro-static bearing blocks which are attached to the underside of the slip plate to enhance the performance of the test system.

Features

- High moment resistance

- Low cross-axis acceleration

- Low distortion

- No requirement for a separate hydraulic unit

- Good work efficacy

- Smaller system installation space

Variable Armature Insert Pattern

The option to freely select the table insert pattern on the shaker armature.

- Selecting this option, the armature mass will increase.

- Due to combining with other options; the horizontal slip table, insert pattern may have restrictions

Head Expanders

The purpose of a Head Expander is to allow testing of multiple items simultaneously, or expanding the test area of a shaker for larger test samples.

Head Expanders can increase efficiency, or simply expand your test capabilities on an existing Vibration Test System.

Features

- Increase Efficiency – Test Multiple Items Simultaneously

- Expand Test Capabilities

Resources

Request Quote

Please select the form below relevant to your enquiry:

J230/SA3AM

J230/SA3AM