Product Overview

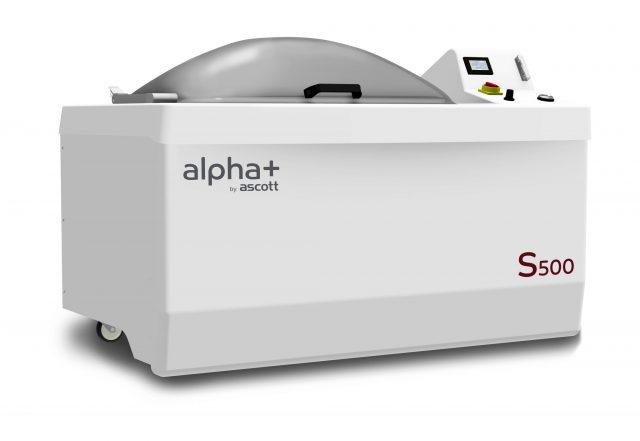

S Series: S500 & S1000

Models: S500 & s1000 salt spray cabinets are the ideal choice for short term tests. (short term test defined as tests of those up to 240 hours’ duration. Tests beyond this duration are defined as long-term tests)

The Alpha+ range by Ascott is designed for ease of use, simple operation and reliability. Easy to install with a minimal number of external service connections. Simple to operate due to intuitive touch screen interface. Reliable and uncomplicated design backed by 25 years manufacturing experience.

Design features:

- Manufactured from a robust glass reinforced plastic (GRP) construction, combined with other non-corroding materials, to guarantee a trouble free long life.

- Visually striking, transparent domed roof providing unimpeded 360 degree viewing of the cabinet interior.

- Latching roof stay for ease of loading.

- Self-regenerating water trap seal, preventing salt fog escaping during operation.

- Ergonomically positioned menu driven touch screen programmer for comfortable and intuitive control.

- Timed stop facility and hours run counter.

- Maximised cross-sectional load area, enabling many samples to be tested at any one time, without compromising ergonomics.

- Supplied with complimentary corrosion proof sample holders.

- Platform available as an optional accessory for large/heavy objects to be located in the base of the cabinet.

International Standards Compliance:

The Alpha+ range complies with the most popular international standards for corrosion testing, including:

- Salt spray standards

- ASTM B117

- ISO 9227

- DIN 50 021

- JIS Z 2371

- Humidity standards

- DIN 50 017-KK

- DIN 50 017-KFW

- DIN 50 017-KTW

- ISO 6270-2

- VDA 621-421

- ASTM D2247

- BS 3900 Part F2

- All cabinets are CE marked as your assurance of their quality and compliance with European directives.

Learn More

Key Features

Key features:

- Designed specifically for short-terms tests (up to 240 hours duration).

- Cabinet heated by externally mounted heater mats, protecting them against damage from the corrosive climate inside the cabinet, also ensuring uniform heat distribution inside the cabinet.

- Heated bubble tower humidifies the compressed air en-route to the salt fog atomiser, in full compliance with International test standards.

- Bubble tower can be topped up with water automatically, or by hand via the manual filler port.

- Utilises the atomisers’ venturi effect combined with the air pressure regulator and gauge to deliver a uniform and continuous fall-out of salt fog on to the samples under test.

- Supplied with a 90L external salt water solution tank, easier to fill and clean than an integral tank.

- The all plastic atomiser has an integral filter in addition to a filter on the reservoir feed pipe to prevent salt crystal build-up blocking the outlet nozzle and disrupting the test.

- Cabinets can be operated with a wet or dry base.

- Insulated non-transparent roof blanket, offering greater thermal efficiency available as an option.

Available Options

| Product Details | S500 & SP500 | |

| Workspace capacity | Ltrs (cu ft) | 500 (17.6) |

| Workspace internal dimensions | width / ‘a’ mm (inches) | 1076 (42.4) |

| depth / ‘b’ mm (inches) | 683 (26.9) | |

| cabinet height / ‘c’ mm (inches) | 616 (24.3) | |

| roof height / ‘d’ mm (inches) | 250 (9.9) | |

| total height / ‘e’ mm (inches) | 866 (34.2) | |

| Cabinet external dimensions | width / ‘f’ mm (inches) | 1650 (65.0) |

| depth / ‘g’ mm (inches) | 934 (36.8) | |

| height / ‘h’ mm (inches) | 1102 (43.4) | |

| Cabinet Weight | Kg (lbs) | 125 (276) |

| Cabinet Load Capacity | Kg (lbs) | 80 (176) |

| Cabinet colour | White |

| Optional Accessories | 500 L | 1000 L | |

| Option Reference | |||

| Internal base loading platform | ACC15/8 | ACC15/9 | Horizontal removable loading platform, covering the internal base of cabinet, to enable large/heavy test samples to be accommodated directly on the internal base of the cabinet. |

| Extra sample holders | ACC16/7 | ACC16/8 | Additional sample holders |

| Installation kit | ACC22 | A bottle trap to connect between the drain outlet of cabinet and local drain facility, to prevent any smells from entering the cabinet via the drain. Also 3m of drain/exhaust tubing with a selection of couplers, and 3m compressed air hose with hose clips | |

| Fall-out measuring kit | ACC35 | ACC35 | Two 80cm2 funnels and two 0-100ml measuring cylinders, for monitoring salt spray fall-out rate. |

| Hand-held salinity refractometer | ACC100 | ACC100 | A salinity refractometer to give a direct reading of percentage sodium chloride in water, in the range 0 to 28%, from a single drop of salt solution. Can be used to simply and accurately check the concentration of the salt solution to be sprayed. |

| Insulated roof blanket | ACC45/1 | ACC45/2 | An insulated non-transparent blanket for the transparent roof. Improves thermal efficiency to increase cabinet maximum operating temperature and salt spray fall-out range |

| Additional salt solution reservoir | ACC55 | ACC55 | An additional 90Ltrs (23 US Gal) reservoir to the one supplied as standard. |

| Advanced salt solution reservoir | ACC02/* see note | ACC02/* see note | Translucent salt solution tank with a graduated scale for viewing the contents, supplied with a hinged lid for filling & cleaning, mounted on castors.

* ACC02/1 80 Ltr / 21 US gal capacity model * ACC02/2 115 Ltr / 30 US gal capacity model * ACC02/3 160 Ltr / 42 US gal capacity model |

| Air compressor | ACC04/1 | ACC04/1 | Provides continuous supply of oil free compressed air to enable functioning without connection to a local compressed air supply |

| Deioniser | ACC06 | ACC06 | Provides high purity water for topping up the cabinet air saturator, humidity system and for making up salt solution.

* ACC06/1 small model * ACC06/2 medium model * ACC06/3 large model |

| Waste water trough | ACC20 | ACC20 | Where a local floor level drain is unavailable the ACC20 provides a tank into which the cabinet drain outlet is terminated. When full, waste water is automatically pumped to a remote drain located up to 10m/32ft horizontally & 3m/10ft vertically. |

| Exhaust salt scrubber | ACC92 | ACC92 | Removes the majority of highly corrosive salt fog from the cabinet exhaust where it is not possible to vent this outside the building. ACC92/1 – non-recirculating – total loss of water used to condense the salt fog.

ACC92/3 – recirculating- reuses some of the water used to condense the salt fog. |

| Air agitation of salt solution | ACC96 | ACC96 | Uses compressed air bubbles to aid dissolving salt within the salt solution reservoir to create a thoroughly mixed salt solution (only for use with ACC02 advanced salt solution reservoir). |

Resources

Please contact our specialist sales team on:

+44 (0) 1462 481859 or

Contact Us via THP-Systems.com

to request a Datasheet or Brochure.

Request Quote

Please select the form below relevant to your enquiry: